What are the Purchasing Models of the Latest Air Core Inductor Equipment Components?

I. Introduction

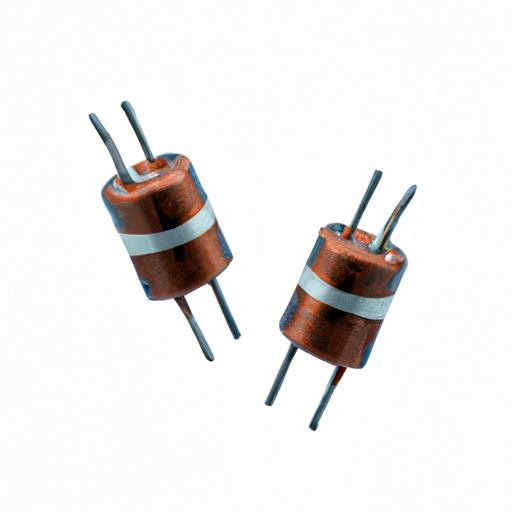

Air core inductors are essential components in modern electronics, playing a crucial role in various applications ranging from radio frequency (RF) circuits to power electronics and audio equipment. Unlike traditional inductors that use a magnetic core, air core inductors rely on air as their core material, which offers several advantages, including low losses, high Q factors, and temperature stability. As the demand for high-performance electronic devices continues to grow, understanding the purchasing models for air core inductor equipment components becomes increasingly important. This blog post will explore the various purchasing models available, the factors influencing purchasing decisions, emerging trends, and case studies that highlight successful implementations.

II. Understanding Air Core Inductors

A. Basic Principles of Inductance

Inductance is the property of an electrical conductor that opposes changes in current. When current flows through a coil of wire, it generates a magnetic field around it. In air core inductors, the absence of a magnetic core minimizes energy losses due to hysteresis and eddy currents, making them ideal for high-frequency applications.

B. Advantages of Air Core Inductors

1. **Low Losses**: Air core inductors exhibit minimal energy losses compared to their iron or ferrite core counterparts, making them suitable for high-efficiency applications.

2. **High Q Factor**: The Q factor, or quality factor, is a measure of an inductor's efficiency. Air core inductors typically have a higher Q factor, which translates to better performance in RF applications.

3. **Temperature Stability**: Air core inductors are less affected by temperature variations, ensuring consistent performance across a range of operating conditions.

C. Applications of Air Core Inductors

1. **RF Applications**: Air core inductors are widely used in RF circuits, including transmitters and receivers, due to their ability to handle high frequencies without significant losses.

2. **Power Electronics**: In power electronics, air core inductors are utilized in converters and inverters, where efficiency is paramount.

3. **Audio Equipment**: High-fidelity audio systems often incorporate air core inductors to maintain signal integrity and minimize distortion.

III. Overview of Purchasing Models

A. Traditional Purchasing Model

1. **Direct Purchase from Manufacturers**: Many companies choose to buy air core inductors directly from manufacturers. This model allows for better pricing and direct communication regarding specifications and requirements.

2. **Distributors and Resellers**: Distributors and resellers provide a convenient option for purchasing air core inductors, often carrying a wide range of products from various manufacturers. This model is beneficial for companies looking for quick access to components without the need for direct negotiations.

B. Online Purchasing Model

1. **E-commerce Platforms**: The rise of e-commerce has transformed the purchasing landscape. Platforms like Digi-Key, Mouser, and Alibaba allow customers to browse and purchase air core inductors from the comfort of their offices, often with detailed specifications and customer reviews.

2. **Manufacturer Websites**: Many manufacturers have developed user-friendly websites that enable customers to order components directly. This model often includes customization options and direct access to technical support.

C. Custom Manufacturing Model

1. **Tailored Solutions for Specific Applications**: Some companies require specialized air core inductors for unique applications. In such cases, custom manufacturing allows for tailored solutions that meet specific performance criteria.

2. **Collaboration with Engineers and Designers**: Custom manufacturing often involves close collaboration between suppliers and the engineering teams of the purchasing company, ensuring that the final product meets all necessary specifications.

IV. Factors Influencing Purchasing Decisions

A. Cost Considerations

1. **Budget Constraints**: Companies must consider their budget when purchasing air core inductors. While high-quality components may come at a premium, the long-term benefits often justify the investment.

2. **Total Cost of Ownership**: Beyond the initial purchase price, companies should evaluate the total cost of ownership, including maintenance, reliability, and potential downtime.

B. Quality and Performance

1. **Specifications and Standards**: Adhering to industry standards and specifications is crucial for ensuring the performance and reliability of air core inductors.

2. **Reliability and Longevity**: The longevity of components is a significant factor in purchasing decisions. High-quality air core inductors can reduce the frequency of replacements and maintenance.

C. Supplier Reputation and Support

1. **Brand Trustworthiness**: Companies often prefer to work with reputable suppliers known for their quality and reliability.

2. **Customer Service and Technical Support**: Access to responsive customer service and technical support can significantly influence purchasing decisions, especially for complex components.

D. Lead Times and Availability

1. **Inventory Management**: Companies must consider lead times and availability when planning their purchases. Delays in receiving components can impact production schedules.

2. **Just-in-Time Delivery**: Many companies are adopting just-in-time delivery models to minimize inventory costs. Suppliers that can accommodate this need are often preferred.

V. Emerging Trends in Purchasing Models

A. Shift Towards Sustainability

1. **Eco-friendly Materials and Manufacturing Processes**: As sustainability becomes a priority, many companies are seeking suppliers that use eco-friendly materials and processes in the production of air core inductors.

2. **Lifecycle Assessment**: Companies are increasingly conducting lifecycle assessments to evaluate the environmental impact of their purchasing decisions.

B. Digital Transformation

1. **Use of AI and Machine Learning in Procurement**: The integration of AI and machine learning in procurement processes is streamlining purchasing decisions, enabling companies to analyze data and predict trends.

2. **Data Analytics for Informed Decision-Making**: Companies are leveraging data analytics to make informed purchasing decisions, ensuring they select the best components for their needs.

C. Global Supply Chain Dynamics

1. **Impact of Geopolitical Factors**: Geopolitical factors can significantly impact the availability and pricing of air core inductors. Companies must stay informed about global events that may affect their supply chains.

2. **Resilience and Risk Management**: Building resilient supply chains and effective risk management strategies is becoming increasingly important in the face of global uncertainties.

VI. Case Studies

A. Successful Implementation of Purchasing Models

1. **Example of a Leading Electronics Manufacturer**: A leading electronics manufacturer successfully implemented a hybrid purchasing model, combining direct purchases from manufacturers with online procurement. This approach allowed them to optimize costs while ensuring access to high-quality components.

2. **Lessons Learned from Industry Leaders**: Industry leaders emphasize the importance of supplier relationships and the need for flexibility in purchasing models to adapt to changing market conditions.

B. Challenges Faced in the Purchasing Process

1. **Supply Chain Disruptions**: Many companies faced significant challenges during the COVID-19 pandemic, highlighting the vulnerabilities in global supply chains.

2. **Quality Control Issues**: Ensuring consistent quality across suppliers remains a challenge, necessitating rigorous quality control measures.

VII. Conclusion

In conclusion, the purchasing models for air core inductor equipment components are evolving in response to technological advancements, market demands, and sustainability considerations. Companies must navigate various purchasing models, from traditional direct purchases to online platforms and custom manufacturing, while considering factors such as cost, quality, supplier reputation, and lead times. As emerging trends continue to shape the landscape, organizations that adopt best practices in procurement will be better positioned to succeed in the competitive electronics market.

VIII. References

A comprehensive list of academic journals, industry reports, and manufacturer and supplier websites can provide further insights into the purchasing models of air core inductors and their applications in modern electronics.

What are the Purchasing Models of the Latest Air Core Inductor Equipment Components?

I. Introduction

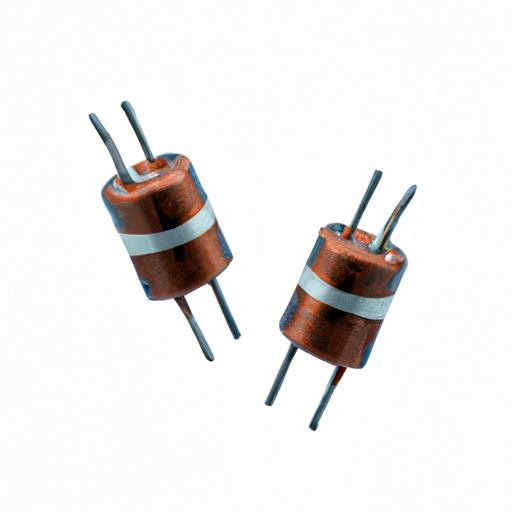

Air core inductors are essential components in modern electronics, playing a crucial role in various applications ranging from radio frequency (RF) circuits to power electronics and audio equipment. Unlike traditional inductors that use a magnetic core, air core inductors rely on air as their core material, which offers several advantages, including low losses, high Q factors, and temperature stability. As the demand for high-performance electronic devices continues to grow, understanding the purchasing models for air core inductor equipment components becomes increasingly important. This blog post will explore the various purchasing models available, the factors influencing purchasing decisions, emerging trends, and case studies that highlight successful implementations.

II. Understanding Air Core Inductors

A. Basic Principles of Inductance

Inductance is the property of an electrical conductor that opposes changes in current. When current flows through a coil of wire, it generates a magnetic field around it. In air core inductors, the absence of a magnetic core minimizes energy losses due to hysteresis and eddy currents, making them ideal for high-frequency applications.

B. Advantages of Air Core Inductors

1. **Low Losses**: Air core inductors exhibit minimal energy losses compared to their iron or ferrite core counterparts, making them suitable for high-efficiency applications.

2. **High Q Factor**: The Q factor, or quality factor, is a measure of an inductor's efficiency. Air core inductors typically have a higher Q factor, which translates to better performance in RF applications.

3. **Temperature Stability**: Air core inductors are less affected by temperature variations, ensuring consistent performance across a range of operating conditions.

C. Applications of Air Core Inductors

1. **RF Applications**: Air core inductors are widely used in RF circuits, including transmitters and receivers, due to their ability to handle high frequencies without significant losses.

2. **Power Electronics**: In power electronics, air core inductors are utilized in converters and inverters, where efficiency is paramount.

3. **Audio Equipment**: High-fidelity audio systems often incorporate air core inductors to maintain signal integrity and minimize distortion.

III. Overview of Purchasing Models

A. Traditional Purchasing Model

1. **Direct Purchase from Manufacturers**: Many companies choose to buy air core inductors directly from manufacturers. This model allows for better pricing and direct communication regarding specifications and requirements.

2. **Distributors and Resellers**: Distributors and resellers provide a convenient option for purchasing air core inductors, often carrying a wide range of products from various manufacturers. This model is beneficial for companies looking for quick access to components without the need for direct negotiations.

B. Online Purchasing Model

1. **E-commerce Platforms**: The rise of e-commerce has transformed the purchasing landscape. Platforms like Digi-Key, Mouser, and Alibaba allow customers to browse and purchase air core inductors from the comfort of their offices, often with detailed specifications and customer reviews.

2. **Manufacturer Websites**: Many manufacturers have developed user-friendly websites that enable customers to order components directly. This model often includes customization options and direct access to technical support.

C. Custom Manufacturing Model

1. **Tailored Solutions for Specific Applications**: Some companies require specialized air core inductors for unique applications. In such cases, custom manufacturing allows for tailored solutions that meet specific performance criteria.

2. **Collaboration with Engineers and Designers**: Custom manufacturing often involves close collaboration between suppliers and the engineering teams of the purchasing company, ensuring that the final product meets all necessary specifications.

IV. Factors Influencing Purchasing Decisions

A. Cost Considerations

1. **Budget Constraints**: Companies must consider their budget when purchasing air core inductors. While high-quality components may come at a premium, the long-term benefits often justify the investment.

2. **Total Cost of Ownership**: Beyond the initial purchase price, companies should evaluate the total cost of ownership, including maintenance, reliability, and potential downtime.

B. Quality and Performance

1. **Specifications and Standards**: Adhering to industry standards and specifications is crucial for ensuring the performance and reliability of air core inductors.

2. **Reliability and Longevity**: The longevity of components is a significant factor in purchasing decisions. High-quality air core inductors can reduce the frequency of replacements and maintenance.

C. Supplier Reputation and Support

1. **Brand Trustworthiness**: Companies often prefer to work with reputable suppliers known for their quality and reliability.

2. **Customer Service and Technical Support**: Access to responsive customer service and technical support can significantly influence purchasing decisions, especially for complex components.

D. Lead Times and Availability

1. **Inventory Management**: Companies must consider lead times and availability when planning their purchases. Delays in receiving components can impact production schedules.

2. **Just-in-Time Delivery**: Many companies are adopting just-in-time delivery models to minimize inventory costs. Suppliers that can accommodate this need are often preferred.

V. Emerging Trends in Purchasing Models

A. Shift Towards Sustainability

1. **Eco-friendly Materials and Manufacturing Processes**: As sustainability becomes a priority, many companies are seeking suppliers that use eco-friendly materials and processes in the production of air core inductors.

2. **Lifecycle Assessment**: Companies are increasingly conducting lifecycle assessments to evaluate the environmental impact of their purchasing decisions.

B. Digital Transformation

1. **Use of AI and Machine Learning in Procurement**: The integration of AI and machine learning in procurement processes is streamlining purchasing decisions, enabling companies to analyze data and predict trends.

2. **Data Analytics for Informed Decision-Making**: Companies are leveraging data analytics to make informed purchasing decisions, ensuring they select the best components for their needs.

C. Global Supply Chain Dynamics

1. **Impact of Geopolitical Factors**: Geopolitical factors can significantly impact the availability and pricing of air core inductors. Companies must stay informed about global events that may affect their supply chains.

2. **Resilience and Risk Management**: Building resilient supply chains and effective risk management strategies is becoming increasingly important in the face of global uncertainties.

VI. Case Studies

A. Successful Implementation of Purchasing Models

1. **Example of a Leading Electronics Manufacturer**: A leading electronics manufacturer successfully implemented a hybrid purchasing model, combining direct purchases from manufacturers with online procurement. This approach allowed them to optimize costs while ensuring access to high-quality components.

2. **Lessons Learned from Industry Leaders**: Industry leaders emphasize the importance of supplier relationships and the need for flexibility in purchasing models to adapt to changing market conditions.

B. Challenges Faced in the Purchasing Process

1. **Supply Chain Disruptions**: Many companies faced significant challenges during the COVID-19 pandemic, highlighting the vulnerabilities in global supply chains.

2. **Quality Control Issues**: Ensuring consistent quality across suppliers remains a challenge, necessitating rigorous quality control measures.

VII. Conclusion

In conclusion, the purchasing models for air core inductor equipment components are evolving in response to technological advancements, market demands, and sustainability considerations. Companies must navigate various purchasing models, from traditional direct purchases to online platforms and custom manufacturing, while considering factors such as cost, quality, supplier reputation, and lead times. As emerging trends continue to shape the landscape, organizations that adopt best practices in procurement will be better positioned to succeed in the competitive electronics market.

VIII. References

A comprehensive list of academic journals, industry reports, and manufacturer and supplier websites can provide further insights into the purchasing models of air core inductors and their applications in modern electronics.