The Development of the Latest Inductors and Purchasing Models of Equipment Components

I. Introduction

Inductors are passive electronic components that store energy in a magnetic field when electrical current flows through them. They play a crucial role in various electronic circuits, serving functions such as filtering, energy storage, and signal processing. As technology advances, so does the design and functionality of inductors, leading to significant improvements in performance and application versatility. This article explores the latest developments in inductor technology and the purchasing models for equipment components, providing insights into how these advancements impact industries ranging from consumer electronics to renewable energy systems.

II. The Evolution of Inductor Technology

A. Historical Context of Inductors

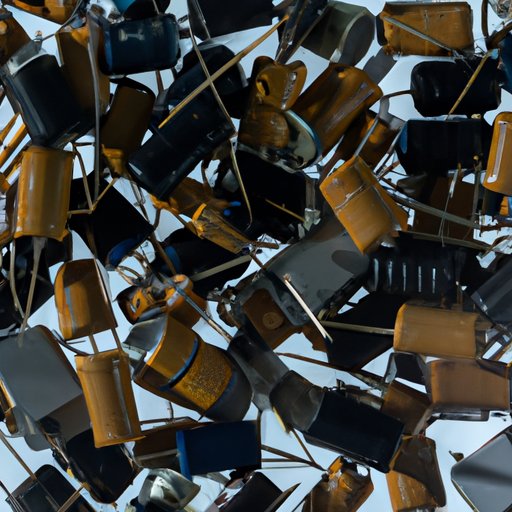

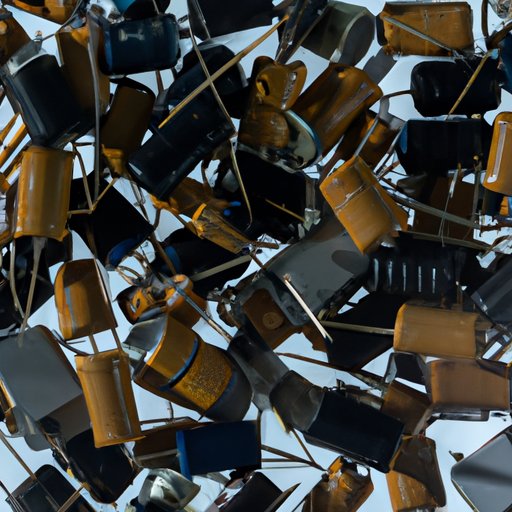

Inductors have a rich history, dating back to the early days of electromagnetism. The first inductors were simple coils of wire, often made from copper, wound around a core material. Over the years, key milestones in inductor development have included the introduction of laminated cores to reduce eddy currents and the use of ferrite materials to enhance inductance and efficiency.

B. Recent Advancements in Inductor Technology

In recent years, inductor technology has seen remarkable advancements. Miniaturization has become a significant trend, driven by the demand for smaller, more efficient electronic devices. Manufacturers are now producing inductors that are not only compact but also capable of handling higher power levels. The use of advanced materials, such as ferrites and powdered iron, has improved performance characteristics, including inductance stability and thermal efficiency.

Innovations in manufacturing processes, such as 3D printing and automated winding techniques, have also revolutionized inductor production. These methods allow for greater precision and customization, enabling the creation of application-specific inductors that meet the unique needs of various industries.

C. Applications of Modern Inductors

Modern inductors find applications across a wide range of sectors. In consumer electronics, they are integral to power supplies, audio equipment, and RF circuits. The automotive industry utilizes inductors in electric vehicles for energy management and battery charging systems. Renewable energy systems, such as solar inverters and wind turbines, rely on inductors for efficient energy conversion. Telecommunications also benefits from advanced inductors, which are essential for signal integrity and noise reduction in high-frequency applications.

III. Key Features of the Latest Inductors

A. Performance Characteristics

The latest inductors boast impressive performance characteristics. Inductance values and tolerances have improved, allowing for more precise control of electrical currents. Current ratings and saturation levels have also been enhanced, enabling inductors to handle higher loads without compromising performance. Additionally, thermal performance and efficiency have become critical design considerations, as manufacturers strive to minimize heat generation and energy loss.

B. Design Considerations

When designing inductors, several factors come into play. Size and form factor are paramount, especially in applications where space is limited. Shielding techniques are employed to reduce electromagnetic interference (EMI), ensuring that inductors do not disrupt the operation of nearby components. Environmental considerations, such as compliance with RoHS (Restriction of Hazardous Substances) regulations, are also essential, as manufacturers seek to produce eco-friendly products.

C. Trends in Inductor Design

Customization is a growing trend in inductor design, with manufacturers increasingly offering application-specific solutions. Smart inductors, which integrate sensors and communication capabilities, are emerging as a key innovation, particularly in the context of the Internet of Things (IoT). These inductors can provide real-time data on performance and health, enabling predictive maintenance and enhanced system efficiency.

IV. Purchasing Models for Equipment Components

A. Overview of Purchasing Models

The procurement of equipment components, including inductors, can follow various purchasing models. Direct purchasing involves buying components straight from manufacturers, which can lead to cost savings but may require larger order quantities. Distributor partnerships offer a balance between cost and convenience, as distributors often maintain stock and provide additional services. Online marketplaces have also gained popularity, providing a platform for buyers to compare prices and availability from multiple suppliers.

B. Factors Influencing Purchasing Decisions

Several factors influence purchasing decisions for inductors and other components. Cost considerations are always at the forefront, as companies seek to minimize expenses while maintaining quality. Quality and reliability are critical, as defective components can lead to costly failures in electronic systems. Lead times and availability are also significant, particularly in industries where time-to-market is crucial. Technical support and service from suppliers can further influence decisions, as companies often require assistance with integration and troubleshooting.

C. Evaluating Suppliers

When evaluating suppliers, companies should establish clear criteria for selection. Factors such as certifications, industry standards, and past performance are essential in determining a supplier's reliability. Building long-term relationships with suppliers can also be beneficial, as it fosters collaboration and ensures a consistent supply of high-quality components.

V. Case Studies

A. Successful Implementation of Advanced Inductors in Consumer Electronics

One notable case study involves a leading smartphone manufacturer that integrated advanced inductors into its latest device. By utilizing miniaturized inductors with high current ratings, the company was able to enhance battery efficiency and reduce the overall size of the device, leading to a more compact and powerful product.

B. Innovations in Automotive Applications

In the automotive sector, a major electric vehicle manufacturer adopted custom-designed inductors for its battery management system. These inductors, optimized for high efficiency and thermal performance, contributed to improved energy management and extended battery life, showcasing the importance of tailored solutions in modern applications.

C. Renewable Energy Systems Utilizing Cutting-Edge Inductors

A renewable energy company successfully implemented advanced inductors in its solar inverter systems. By leveraging inductors with superior thermal performance and efficiency, the company achieved higher energy conversion rates, resulting in increased power output and reduced operational costs.

VI. Future Trends in Inductor Development and Purchasing

A. Anticipated Technological Advancements

Looking ahead, several technological advancements are anticipated in inductor development. The integration of smart technologies will likely become more prevalent, enabling inductors to communicate with other components and systems. Additionally, the use of sustainable materials and practices will gain traction as industries strive to reduce their environmental impact.

B. Evolving Purchasing Models

The rise of e-commerce is transforming component procurement, making it easier for companies to access a wider range of suppliers and products. The role of AI and data analytics in purchasing decisions is also expected to grow, allowing companies to make more informed choices based on real-time data and market trends.

VII. Conclusion

In summary, the development of the latest inductors reflects significant advancements in technology, materials, and manufacturing processes. These improvements have expanded the applications of inductors across various industries, from consumer electronics to renewable energy systems. Understanding the purchasing models for equipment components is equally important, as companies navigate the complexities of procurement in a rapidly evolving market. Staying updated with inductor technology and purchasing strategies will be crucial for businesses aiming to remain competitive in the electronics industry.

VIII. References

1. Smith, J. (2022). "Advancements in Inductor Technology: A Comprehensive Review." *Journal of Electronics Engineering*.

2. Brown, L. (2023). "The Role of Inductors in Modern Electronics." *Electronics Today*.

3. Green, T. (2023). "Sustainable Practices in Component Manufacturing." *Renewable Energy Journal*.

4. White, R. (2023). "E-commerce Trends in Electronic Component Procurement." *Supply Chain Management Review*.

This blog post provides a comprehensive overview of the latest developments in inductor technology and the purchasing models for equipment components, highlighting the importance of these advancements in the electronics industry.

The Development of the Latest Inductors and Purchasing Models of Equipment Components

I. Introduction

Inductors are passive electronic components that store energy in a magnetic field when electrical current flows through them. They play a crucial role in various electronic circuits, serving functions such as filtering, energy storage, and signal processing. As technology advances, so does the design and functionality of inductors, leading to significant improvements in performance and application versatility. This article explores the latest developments in inductor technology and the purchasing models for equipment components, providing insights into how these advancements impact industries ranging from consumer electronics to renewable energy systems.

II. The Evolution of Inductor Technology

A. Historical Context of Inductors

Inductors have a rich history, dating back to the early days of electromagnetism. The first inductors were simple coils of wire, often made from copper, wound around a core material. Over the years, key milestones in inductor development have included the introduction of laminated cores to reduce eddy currents and the use of ferrite materials to enhance inductance and efficiency.

B. Recent Advancements in Inductor Technology

In recent years, inductor technology has seen remarkable advancements. Miniaturization has become a significant trend, driven by the demand for smaller, more efficient electronic devices. Manufacturers are now producing inductors that are not only compact but also capable of handling higher power levels. The use of advanced materials, such as ferrites and powdered iron, has improved performance characteristics, including inductance stability and thermal efficiency.

Innovations in manufacturing processes, such as 3D printing and automated winding techniques, have also revolutionized inductor production. These methods allow for greater precision and customization, enabling the creation of application-specific inductors that meet the unique needs of various industries.

C. Applications of Modern Inductors

Modern inductors find applications across a wide range of sectors. In consumer electronics, they are integral to power supplies, audio equipment, and RF circuits. The automotive industry utilizes inductors in electric vehicles for energy management and battery charging systems. Renewable energy systems, such as solar inverters and wind turbines, rely on inductors for efficient energy conversion. Telecommunications also benefits from advanced inductors, which are essential for signal integrity and noise reduction in high-frequency applications.

III. Key Features of the Latest Inductors

A. Performance Characteristics

The latest inductors boast impressive performance characteristics. Inductance values and tolerances have improved, allowing for more precise control of electrical currents. Current ratings and saturation levels have also been enhanced, enabling inductors to handle higher loads without compromising performance. Additionally, thermal performance and efficiency have become critical design considerations, as manufacturers strive to minimize heat generation and energy loss.

B. Design Considerations

When designing inductors, several factors come into play. Size and form factor are paramount, especially in applications where space is limited. Shielding techniques are employed to reduce electromagnetic interference (EMI), ensuring that inductors do not disrupt the operation of nearby components. Environmental considerations, such as compliance with RoHS (Restriction of Hazardous Substances) regulations, are also essential, as manufacturers seek to produce eco-friendly products.

C. Trends in Inductor Design

Customization is a growing trend in inductor design, with manufacturers increasingly offering application-specific solutions. Smart inductors, which integrate sensors and communication capabilities, are emerging as a key innovation, particularly in the context of the Internet of Things (IoT). These inductors can provide real-time data on performance and health, enabling predictive maintenance and enhanced system efficiency.

IV. Purchasing Models for Equipment Components

A. Overview of Purchasing Models

The procurement of equipment components, including inductors, can follow various purchasing models. Direct purchasing involves buying components straight from manufacturers, which can lead to cost savings but may require larger order quantities. Distributor partnerships offer a balance between cost and convenience, as distributors often maintain stock and provide additional services. Online marketplaces have also gained popularity, providing a platform for buyers to compare prices and availability from multiple suppliers.

B. Factors Influencing Purchasing Decisions

Several factors influence purchasing decisions for inductors and other components. Cost considerations are always at the forefront, as companies seek to minimize expenses while maintaining quality. Quality and reliability are critical, as defective components can lead to costly failures in electronic systems. Lead times and availability are also significant, particularly in industries where time-to-market is crucial. Technical support and service from suppliers can further influence decisions, as companies often require assistance with integration and troubleshooting.

C. Evaluating Suppliers

When evaluating suppliers, companies should establish clear criteria for selection. Factors such as certifications, industry standards, and past performance are essential in determining a supplier's reliability. Building long-term relationships with suppliers can also be beneficial, as it fosters collaboration and ensures a consistent supply of high-quality components.

V. Case Studies

A. Successful Implementation of Advanced Inductors in Consumer Electronics

One notable case study involves a leading smartphone manufacturer that integrated advanced inductors into its latest device. By utilizing miniaturized inductors with high current ratings, the company was able to enhance battery efficiency and reduce the overall size of the device, leading to a more compact and powerful product.

B. Innovations in Automotive Applications

In the automotive sector, a major electric vehicle manufacturer adopted custom-designed inductors for its battery management system. These inductors, optimized for high efficiency and thermal performance, contributed to improved energy management and extended battery life, showcasing the importance of tailored solutions in modern applications.

C. Renewable Energy Systems Utilizing Cutting-Edge Inductors

A renewable energy company successfully implemented advanced inductors in its solar inverter systems. By leveraging inductors with superior thermal performance and efficiency, the company achieved higher energy conversion rates, resulting in increased power output and reduced operational costs.

VI. Future Trends in Inductor Development and Purchasing

A. Anticipated Technological Advancements

Looking ahead, several technological advancements are anticipated in inductor development. The integration of smart technologies will likely become more prevalent, enabling inductors to communicate with other components and systems. Additionally, the use of sustainable materials and practices will gain traction as industries strive to reduce their environmental impact.

B. Evolving Purchasing Models

The rise of e-commerce is transforming component procurement, making it easier for companies to access a wider range of suppliers and products. The role of AI and data analytics in purchasing decisions is also expected to grow, allowing companies to make more informed choices based on real-time data and market trends.

VII. Conclusion

In summary, the development of the latest inductors reflects significant advancements in technology, materials, and manufacturing processes. These improvements have expanded the applications of inductors across various industries, from consumer electronics to renewable energy systems. Understanding the purchasing models for equipment components is equally important, as companies navigate the complexities of procurement in a rapidly evolving market. Staying updated with inductor technology and purchasing strategies will be crucial for businesses aiming to remain competitive in the electronics industry.

VIII. References

1. Smith, J. (2022). "Advancements in Inductor Technology: A Comprehensive Review." *Journal of Electronics Engineering*.

2. Brown, L. (2023). "The Role of Inductors in Modern Electronics." *Electronics Today*.

3. Green, T. (2023). "Sustainable Practices in Component Manufacturing." *Renewable Energy Journal*.

4. White, R. (2023). "E-commerce Trends in Electronic Component Procurement." *Supply Chain Management Review*.

This blog post provides a comprehensive overview of the latest developments in inductor technology and the purchasing models for equipment components, highlighting the importance of these advancements in the electronics industry.