The Production Process of Mainstream Capacitor Equipment

I. Introduction

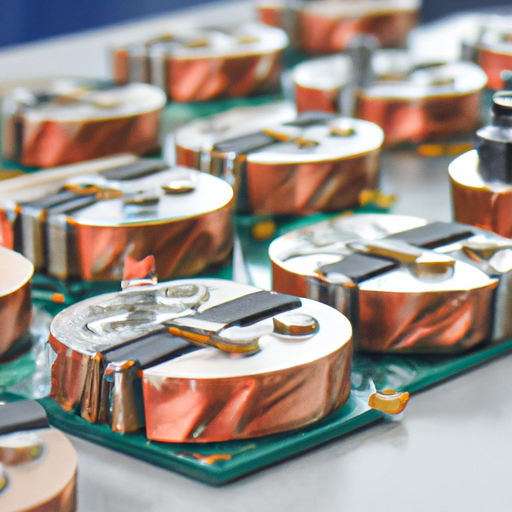

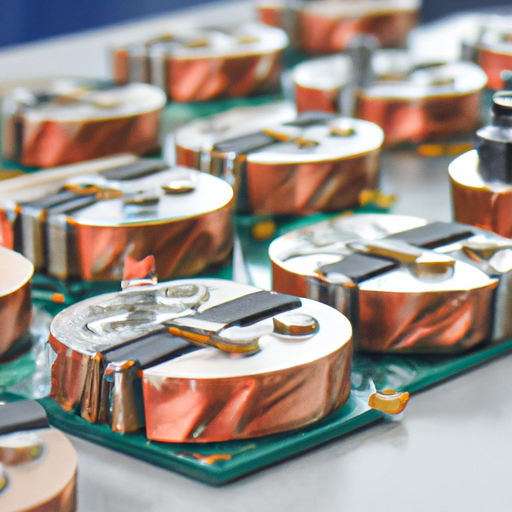

Capacitors are essential components in electronic devices, serving as energy storage units that help regulate voltage and power flow. They play a critical role in various applications, from consumer electronics to industrial machinery. The capacitor manufacturing industry has evolved significantly over the years, driven by advancements in technology and increasing demand for high-performance electronic components. This article aims to explore the production process of mainstream capacitor equipment, shedding light on the intricate steps involved in bringing these vital components to market.

II. Types of Capacitors

Capacitors come in various types, each designed for specific applications and performance characteristics.

A. Overview of Different Types of Capacitors

1. **Ceramic Capacitors**: Known for their small size and high capacitance values, ceramic capacitors are widely used in high-frequency applications. They are made from ceramic materials that serve as the dielectric.

2. **Electrolytic Capacitors**: These capacitors are characterized by their high capacitance and are often used in power supply circuits. They utilize an electrolyte as one of the plates, allowing for larger capacitance values in a compact form.

3. **Film Capacitors**: Made from thin plastic films, these capacitors are known for their stability and reliability. They are commonly used in audio and power applications due to their low loss characteristics.

4. **Tantalum Capacitors**: Tantalum capacitors are known for their high capacitance and voltage ratings in a small package. They are often used in applications where space is limited, such as in mobile devices.

B. Applications of Each Type in Various Industries

Each type of capacitor finds its niche in different industries. For instance, ceramic capacitors are prevalent in telecommunications, while electrolytic capacitors are commonly found in power electronics. Film capacitors are favored in audio equipment, and tantalum capacitors are often used in aerospace and military applications due to their reliability.

III. Raw Materials Used in Capacitor Production

The production of capacitors relies on several key raw materials, each contributing to the performance and reliability of the final product.

A. Description of Key Raw Materials

1. **Dielectric Materials**: The dielectric material is crucial for a capacitor's function, as it separates the conductive plates and stores electrical energy. Common dielectric materials include ceramic, polyester, and tantalum oxide.

2. **Conductive Materials**: These materials form the electrodes of the capacitor. Common choices include aluminum and tantalum, which are selected based on their conductivity and compatibility with the dielectric.

3. **Packaging Materials**: The packaging protects the capacitor from environmental factors and mechanical stress. Materials such as epoxy resins and plastics are commonly used for encapsulation.

B. Sourcing and Quality Control of Raw Materials

Sourcing high-quality raw materials is vital for ensuring the performance and longevity of capacitors. Manufacturers often establish relationships with trusted suppliers and implement rigorous quality control measures to verify the integrity of the materials used in production.

IV. The Production Process

The production of capacitors involves several intricate steps, each requiring precision and expertise.

A. Design and Engineering

1. **Initial Design Considerations**: The production process begins with the design phase, where engineers consider factors such as capacitance value, voltage rating, and physical dimensions.

2. **Simulation and Modeling**: Advanced simulation tools are used to model the capacitor's performance under various conditions, allowing engineers to optimize the design before moving to production.

B. Manufacturing Steps

1. **Dielectric Layer Preparation**:

- **Material Selection**: The choice of dielectric material is critical, as it affects the capacitor's performance.

- **Layer Deposition Techniques**: Techniques such as screen printing or sputtering are employed to create the dielectric layer with the desired thickness and uniformity.

2. **Electrode Fabrication**:

- **Material Choices**: Depending on the capacitor type, materials like aluminum or tantalum are selected for the electrodes.

- **Methods of Electrode Application**: Techniques such as vapor deposition or chemical etching are used to apply the electrodes to the dielectric layer.

3. **Assembly of Capacitor Components**:

- **Layer Stacking**: For multi-layer capacitors, layers of dielectric and electrodes are stacked to achieve the desired capacitance.

- **Connection of Electrodes**: The electrodes are connected using conductive adhesives or soldering techniques to ensure electrical continuity.

4. **Encapsulation and Packaging**:

- **Types of Encapsulation**: Capacitors may be encapsulated using various methods, including potting or molding, to protect them from environmental factors.

- **Importance of Packaging in Performance and Safety**: Proper packaging is essential for ensuring the capacitor's reliability and safety in operation.

C. Quality Assurance and Testing

1. **In-Process Quality Checks**: Throughout the manufacturing process, quality checks are conducted to ensure that each component meets the required specifications.

2. **Final Testing Procedures**: Once assembled, capacitors undergo rigorous testing to verify their performance, including capacitance, leakage current, and voltage ratings.

3. **Certification and Compliance with Industry Standards**: Capacitors must comply with industry standards such as IEC and UL to ensure safety and reliability in their applications.

V. Automation and Technology in Capacitor Production

The capacitor manufacturing process has seen significant advancements due to automation and technology.

A. Role of Automation in Manufacturing Efficiency

Automation has streamlined the production process, reducing labor costs and increasing efficiency. Automated systems can perform repetitive tasks with high precision, minimizing the risk of human error.

B. Advanced Technologies Used in Production

1. **Robotics**: Robotic systems are employed for tasks such as material handling and assembly, enhancing speed and accuracy.

2. **AI and Machine Learning**: These technologies are used to analyze production data, optimize processes, and predict maintenance needs, leading to improved efficiency.

3. **IoT in Monitoring Production Processes**: The Internet of Things (IoT) enables real-time monitoring of production processes, allowing manufacturers to identify issues quickly and maintain optimal performance.

VI. Environmental Considerations

As the capacitor manufacturing industry grows, so does the need for sustainable practices.

A. Sustainability in Capacitor Production

1. **Waste Management Practices**: Manufacturers are implementing waste reduction strategies, recycling materials, and minimizing hazardous waste.

2. **Use of Eco-Friendly Materials**: There is a growing trend towards using environmentally friendly materials in capacitor production, reducing the industry's overall environmental impact.

B. Regulatory Compliance and Environmental Impact Assessments

Manufacturers must comply with environmental regulations and conduct impact assessments to ensure their operations do not harm the environment.

VII. Challenges in Capacitor Manufacturing

Despite advancements, the capacitor manufacturing industry faces several challenges.

A. Supply Chain Issues

Global supply chain disruptions can impact the availability of raw materials, leading to production delays and increased costs.

B. Technological Advancements and Adaptation

Keeping up with rapid technological advancements requires continuous investment in research and development, which can be a significant challenge for manufacturers.

C. Market Demand Fluctuations

The demand for capacitors can fluctuate based on market trends, requiring manufacturers to be agile and responsive to changes in consumer needs.

VIII. Future Trends in Capacitor Production

The future of capacitor manufacturing is poised for exciting developments.

A. Innovations in Materials and Design

Research into new materials and designs is ongoing, with the potential to create capacitors that are smaller, more efficient, and capable of higher performance.

B. The Impact of Electric Vehicles and Renewable Energy on Capacitor Demand

The rise of electric vehicles and renewable energy technologies is driving demand for advanced capacitors, particularly in energy storage applications.

C. Predictions for the Future of Capacitor Manufacturing

As technology continues to evolve, the capacitor manufacturing industry is expected to grow, with increased focus on sustainability and innovation.

IX. Conclusion

Capacitors are integral to modern electronics, and their production involves a complex process that requires precision and expertise. From the selection of raw materials to the final testing of products, each step is crucial in ensuring the performance and reliability of capacitors. As the industry faces challenges and embraces new technologies, the future of capacitor manufacturing looks promising, with opportunities for innovation and growth.

X. References

A comprehensive list of academic papers, industry reports, and other resources would be included here to support the information presented in the article.

---

This blog post provides a detailed overview of the production process of mainstream capacitor equipment, highlighting the complexities and innovations within the industry. Each section can be further expanded or refined based on specific interests or audience needs.

The Production Process of Mainstream Capacitor Equipment

I. Introduction

Capacitors are essential components in electronic devices, serving as energy storage units that help regulate voltage and power flow. They play a critical role in various applications, from consumer electronics to industrial machinery. The capacitor manufacturing industry has evolved significantly over the years, driven by advancements in technology and increasing demand for high-performance electronic components. This article aims to explore the production process of mainstream capacitor equipment, shedding light on the intricate steps involved in bringing these vital components to market.

II. Types of Capacitors

Capacitors come in various types, each designed for specific applications and performance characteristics.

A. Overview of Different Types of Capacitors

1. **Ceramic Capacitors**: Known for their small size and high capacitance values, ceramic capacitors are widely used in high-frequency applications. They are made from ceramic materials that serve as the dielectric.

2. **Electrolytic Capacitors**: These capacitors are characterized by their high capacitance and are often used in power supply circuits. They utilize an electrolyte as one of the plates, allowing for larger capacitance values in a compact form.

3. **Film Capacitors**: Made from thin plastic films, these capacitors are known for their stability and reliability. They are commonly used in audio and power applications due to their low loss characteristics.

4. **Tantalum Capacitors**: Tantalum capacitors are known for their high capacitance and voltage ratings in a small package. They are often used in applications where space is limited, such as in mobile devices.

B. Applications of Each Type in Various Industries

Each type of capacitor finds its niche in different industries. For instance, ceramic capacitors are prevalent in telecommunications, while electrolytic capacitors are commonly found in power electronics. Film capacitors are favored in audio equipment, and tantalum capacitors are often used in aerospace and military applications due to their reliability.

III. Raw Materials Used in Capacitor Production

The production of capacitors relies on several key raw materials, each contributing to the performance and reliability of the final product.

A. Description of Key Raw Materials

1. **Dielectric Materials**: The dielectric material is crucial for a capacitor's function, as it separates the conductive plates and stores electrical energy. Common dielectric materials include ceramic, polyester, and tantalum oxide.

2. **Conductive Materials**: These materials form the electrodes of the capacitor. Common choices include aluminum and tantalum, which are selected based on their conductivity and compatibility with the dielectric.

3. **Packaging Materials**: The packaging protects the capacitor from environmental factors and mechanical stress. Materials such as epoxy resins and plastics are commonly used for encapsulation.

B. Sourcing and Quality Control of Raw Materials

Sourcing high-quality raw materials is vital for ensuring the performance and longevity of capacitors. Manufacturers often establish relationships with trusted suppliers and implement rigorous quality control measures to verify the integrity of the materials used in production.

IV. The Production Process

The production of capacitors involves several intricate steps, each requiring precision and expertise.

A. Design and Engineering

1. **Initial Design Considerations**: The production process begins with the design phase, where engineers consider factors such as capacitance value, voltage rating, and physical dimensions.

2. **Simulation and Modeling**: Advanced simulation tools are used to model the capacitor's performance under various conditions, allowing engineers to optimize the design before moving to production.

B. Manufacturing Steps

1. **Dielectric Layer Preparation**:

- **Material Selection**: The choice of dielectric material is critical, as it affects the capacitor's performance.

- **Layer Deposition Techniques**: Techniques such as screen printing or sputtering are employed to create the dielectric layer with the desired thickness and uniformity.

2. **Electrode Fabrication**:

- **Material Choices**: Depending on the capacitor type, materials like aluminum or tantalum are selected for the electrodes.

- **Methods of Electrode Application**: Techniques such as vapor deposition or chemical etching are used to apply the electrodes to the dielectric layer.

3. **Assembly of Capacitor Components**:

- **Layer Stacking**: For multi-layer capacitors, layers of dielectric and electrodes are stacked to achieve the desired capacitance.

- **Connection of Electrodes**: The electrodes are connected using conductive adhesives or soldering techniques to ensure electrical continuity.

4. **Encapsulation and Packaging**:

- **Types of Encapsulation**: Capacitors may be encapsulated using various methods, including potting or molding, to protect them from environmental factors.

- **Importance of Packaging in Performance and Safety**: Proper packaging is essential for ensuring the capacitor's reliability and safety in operation.

C. Quality Assurance and Testing

1. **In-Process Quality Checks**: Throughout the manufacturing process, quality checks are conducted to ensure that each component meets the required specifications.

2. **Final Testing Procedures**: Once assembled, capacitors undergo rigorous testing to verify their performance, including capacitance, leakage current, and voltage ratings.

3. **Certification and Compliance with Industry Standards**: Capacitors must comply with industry standards such as IEC and UL to ensure safety and reliability in their applications.

V. Automation and Technology in Capacitor Production

The capacitor manufacturing process has seen significant advancements due to automation and technology.

A. Role of Automation in Manufacturing Efficiency

Automation has streamlined the production process, reducing labor costs and increasing efficiency. Automated systems can perform repetitive tasks with high precision, minimizing the risk of human error.

B. Advanced Technologies Used in Production

1. **Robotics**: Robotic systems are employed for tasks such as material handling and assembly, enhancing speed and accuracy.

2. **AI and Machine Learning**: These technologies are used to analyze production data, optimize processes, and predict maintenance needs, leading to improved efficiency.

3. **IoT in Monitoring Production Processes**: The Internet of Things (IoT) enables real-time monitoring of production processes, allowing manufacturers to identify issues quickly and maintain optimal performance.

VI. Environmental Considerations

As the capacitor manufacturing industry grows, so does the need for sustainable practices.

A. Sustainability in Capacitor Production

1. **Waste Management Practices**: Manufacturers are implementing waste reduction strategies, recycling materials, and minimizing hazardous waste.

2. **Use of Eco-Friendly Materials**: There is a growing trend towards using environmentally friendly materials in capacitor production, reducing the industry's overall environmental impact.

B. Regulatory Compliance and Environmental Impact Assessments

Manufacturers must comply with environmental regulations and conduct impact assessments to ensure their operations do not harm the environment.

VII. Challenges in Capacitor Manufacturing

Despite advancements, the capacitor manufacturing industry faces several challenges.

A. Supply Chain Issues

Global supply chain disruptions can impact the availability of raw materials, leading to production delays and increased costs.

B. Technological Advancements and Adaptation

Keeping up with rapid technological advancements requires continuous investment in research and development, which can be a significant challenge for manufacturers.

C. Market Demand Fluctuations

The demand for capacitors can fluctuate based on market trends, requiring manufacturers to be agile and responsive to changes in consumer needs.

VIII. Future Trends in Capacitor Production

The future of capacitor manufacturing is poised for exciting developments.

A. Innovations in Materials and Design

Research into new materials and designs is ongoing, with the potential to create capacitors that are smaller, more efficient, and capable of higher performance.

B. The Impact of Electric Vehicles and Renewable Energy on Capacitor Demand

The rise of electric vehicles and renewable energy technologies is driving demand for advanced capacitors, particularly in energy storage applications.

C. Predictions for the Future of Capacitor Manufacturing

As technology continues to evolve, the capacitor manufacturing industry is expected to grow, with increased focus on sustainability and innovation.

IX. Conclusion

Capacitors are integral to modern electronics, and their production involves a complex process that requires precision and expertise. From the selection of raw materials to the final testing of products, each step is crucial in ensuring the performance and reliability of capacitors. As the industry faces challenges and embraces new technologies, the future of capacitor manufacturing looks promising, with opportunities for innovation and growth.

X. References

A comprehensive list of academic papers, industry reports, and other resources would be included here to support the information presented in the article.

---

This blog post provides a detailed overview of the production process of mainstream capacitor equipment, highlighting the complexities and innovations within the industry. Each section can be further expanded or refined based on specific interests or audience needs.