Please choose online customer service:

Important Product Categories of Wirewound Inductors

I. Introduction

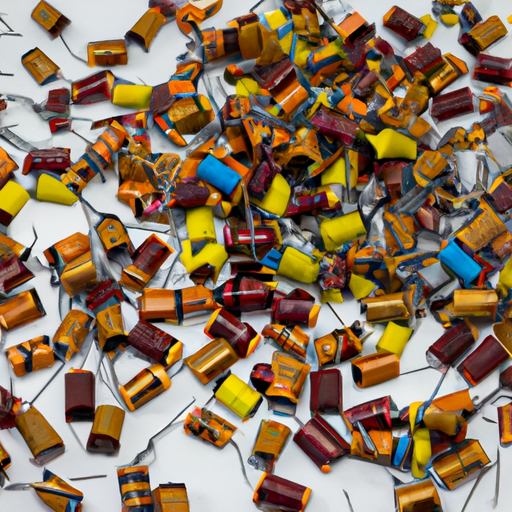

Wirewound inductors are essential components in electronic circuits, playing a crucial role in managing electrical energy. These inductors are constructed by winding a wire around a core, which can be made from various materials, to create a magnetic field that stores energy. Their ability to store and release energy makes them invaluable in applications ranging from power supplies to radio frequency circuits. This article aims to explore the important product categories of wirewound inductors, highlighting their characteristics, applications, and significance in modern electronics.

II. Basic Principles of Wirewound Inductors

A. Explanation of Inductance and Its Role in Circuits

Inductance is the property of an electrical component that allows it to store energy in a magnetic field when an electric current passes through it. This property is fundamental to the operation of inductors, as it enables them to resist changes in current, filter signals, and store energy for later use. In circuits, inductors are used to smooth out fluctuations in current, filter out noise, and provide energy storage.

B. Construction and Materials Used in Wirewound Inductors

Wirewound inductors are typically constructed by winding insulated copper wire around a core made of ferromagnetic material, such as iron or ferrite. The choice of core material affects the inductor's performance, including its inductance value, saturation current, and efficiency. The wire gauge, number of turns, and winding technique also play significant roles in determining the inductor's characteristics.

C. How Wirewound Inductors Differ from Other Types of Inductors

Wirewound inductors differ from other types of inductors, such as ceramic or air-core inductors, primarily in their construction and performance characteristics. Wirewound inductors generally offer higher inductance values and better energy storage capabilities due to their magnetic cores. However, they may also have higher DC resistance and can be bulkier than other types, making them suitable for specific applications where size and weight are less critical.

III. Key Product Categories of Wirewound Inductors

A. Power Inductors

1. Definition and Applications

Power inductors are designed to handle high current levels and are commonly used in power supply circuits, DC-DC converters, and energy storage applications. They are essential for managing power flow and ensuring stable operation in electronic devices.

2. Characteristics and Specifications

Power inductors typically feature low DC resistance, high saturation current ratings, and robust thermal performance. They are designed to minimize energy losses and maintain efficiency under varying load conditions.

3. Examples of Power Inductor Products

Examples of power inductors include the Murata LQH32CN series and the Coilcraft XAL series, both of which are widely used in power management applications.

B. RF Inductors

1. Definition and Applications in Radio Frequency Circuits

RF inductors are specialized inductors designed for use in radio frequency applications, such as RF amplifiers, oscillators, and filters. They are optimized for high-frequency performance and low losses.

2. Characteristics and Specifications

RF inductors typically have low self-resonant frequencies, high Q factors, and minimal parasitic capacitance. These characteristics are crucial for maintaining signal integrity in high-frequency circuits.

3. Examples of RF Inductor Products

Notable RF inductor products include the Wurth Elektronik 744311 series and the Vishay IHLP series, which are commonly used in RF applications.

C. Choke Inductors

1. Definition and Applications in Filtering and Energy Storage

Choke inductors are used primarily for filtering applications, where they block high-frequency AC signals while allowing DC or low-frequency signals to pass. They are commonly found in power supplies and audio equipment.

2. Characteristics and Specifications

Choke inductors are characterized by their inductance value, current rating, and DC resistance. They are designed to handle specific frequency ranges and provide effective filtering.

3. Examples of Choke Inductor Products

Examples of choke inductors include the Bourns SRF series and the Panasonic EEH-ZS series, which are widely used in various filtering applications.

D. Current Sense Inductors

1. Definition and Applications in Current Measurement

Current sense inductors are designed to measure the current flowing through a circuit by generating a voltage proportional to the current. They are commonly used in power management and monitoring applications.

2. Characteristics and Specifications

These inductors typically feature low DC resistance, high accuracy, and a compact design. They are essential for applications requiring precise current measurement and monitoring.

3. Examples of Current Sense Inductor Products

Examples of current sense inductors include the Coilcraft MSS series and the Vishay IHLP series, which are used in various current sensing applications.

E. High-Frequency Inductors

1. Definition and Applications in High-Speed Circuits

High-frequency inductors are designed for use in high-speed circuits, such as digital signal processing and RF applications. They are optimized for minimal losses at high frequencies.

2. Characteristics and Specifications

High-frequency inductors typically have low parasitic capacitance, high Q factors, and a compact design. These characteristics are crucial for maintaining signal integrity in high-speed applications.

3. Examples of High-Frequency Inductor Products

Examples of high-frequency inductors include the Murata LQG series and the Coilcraft 0805 series, which are widely used in high-speed circuits.

F. Custom Inductors

1. Definition and Applications for Specialized Needs

Custom inductors are designed to meet specific requirements for unique applications. They can be tailored in terms of inductance value, size, and performance characteristics.

2. Characteristics and Specifications

Custom inductors can vary widely in specifications, depending on the application. They may be designed for high power, high frequency, or specific environmental conditions.

3. Examples of Custom Inductor Products

Many manufacturers offer custom inductor solutions, such as Coilcraft and Würth Elektronik, which can design inductors to meet specific customer needs.

IV. Factors Influencing the Selection of Wirewound Inductors

When selecting wirewound inductors for a specific application, several factors must be considered:

A. Inductance Value and Tolerance

The inductance value must match the requirements of the circuit, and the tolerance indicates how much the actual inductance can vary from the specified value.

B. Current Rating and Saturation Current

The current rating indicates the maximum continuous current the inductor can handle, while the saturation current is the point at which the inductor's inductance begins to decrease significantly.

C. DC Resistance and Temperature Coefficient

Low DC resistance is desirable to minimize energy losses, while the temperature coefficient indicates how the inductance value changes with temperature.

D. Size and Form Factor Considerations

The physical size and form factor of the inductor must fit within the design constraints of the circuit, especially in compact electronic devices.

E. Environmental Factors and Compliance Standards

Consideration of environmental factors, such as temperature, humidity, and vibration, is essential, as well as compliance with industry standards and regulations.

V. Applications of Wirewound Inductors

Wirewound inductors find applications across various industries, including:

A. Consumer Electronics

In consumer electronics, wirewound inductors are used in power supplies, audio equipment, and signal processing circuits.

B. Automotive Applications

In the automotive industry, they are used in power management systems, electric vehicle charging, and infotainment systems.

C. Industrial Equipment

Wirewound inductors are essential in industrial equipment for motor control, power conversion, and energy storage applications.

D. Telecommunications

In telecommunications, they are used in signal filtering, RF amplification, and data transmission systems.

E. Medical Devices

In medical devices, wirewound inductors play a critical role in power management, signal processing, and imaging systems.

VI. Conclusion

Wirewound inductors are vital components in modern electronic circuits, offering a range of product categories tailored to specific applications. From power inductors to custom solutions, these inductors provide essential functions in energy management, signal processing, and current measurement. As technology continues to evolve, the demand for advanced wirewound inductors will grow, driving innovation and improvements in performance and efficiency.

VII. References

For further exploration of wirewound inductors, consider the following resources:

1. "Inductor Basics" - Electronic Tutorials

2. "Understanding Inductors" - Digi-Key Electronics

3. "Inductor Selection Guide" - Coilcraft

4. "Inductor Design and Applications" - Murata Manufacturing Co., Ltd.

This comprehensive overview of wirewound inductors and their product categories highlights their significance in various applications, ensuring that readers gain a deeper understanding of these essential electronic components.