Please choose online customer service:

What is the Market Prospect of Tantalum Capacitors?

I. Introduction

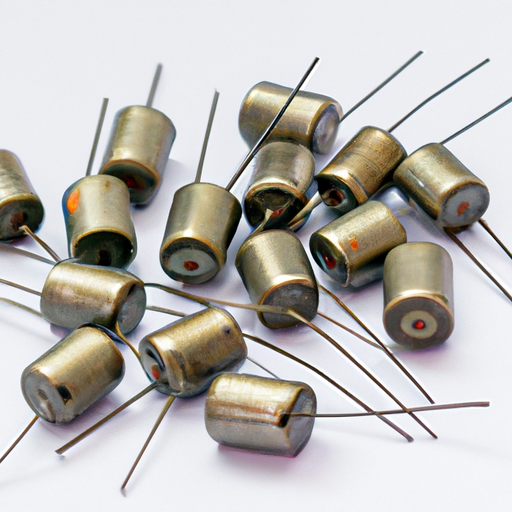

Tantalum capacitors are a type of electrolytic capacitor that utilizes tantalum metal for their anodes. Known for their high capacitance density and reliability, these components play a crucial role in various electronic devices. As technology continues to advance, the demand for tantalum capacitors is expected to grow, making it essential to explore their market prospects. This article aims to provide a comprehensive overview of tantalum capacitors, their current market landscape, applications, growth drivers, challenges, and future trends.

II. Overview of Tantalum Capacitors

A. Composition and Structure

Tantalum capacitors are composed of tantalum powder, which is sintered to form a porous anode. This anode is then coated with a dielectric layer of tantalum pentoxide, which is formed through an anodization process. The combination of these materials results in a capacitor that offers high capacitance in a small package.

1. Materials Used

The primary material used in tantalum capacitors is tantalum, a rare metal known for its excellent conductivity and resistance to corrosion. The dielectric layer is typically made from tantalum oxide, which provides the necessary insulation between the anode and cathode.

2. Manufacturing Process

The manufacturing process of tantalum capacitors involves several steps, including powder preparation, pressing, sintering, anodization, and assembly. Each step is critical to ensuring the performance and reliability of the final product.

B. Types of Tantalum Capacitors

Tantalum capacitors can be categorized into two main types:

1. Solid Tantalum Capacitors

These capacitors use a solid electrolyte and are known for their stability and reliability. They are commonly used in applications where performance is critical.

2. Tantalum Polymer Capacitors

These capacitors utilize a conductive polymer as the electrolyte, offering lower equivalent series resistance (ESR) and improved performance in high-frequency applications.

C. Key Characteristics

Tantalum capacitors are characterized by several key features:

1. High Capacitance Density

One of the most significant advantages of tantalum capacitors is their high capacitance density, allowing for smaller sizes without sacrificing performance.

2. Voltage Ratings

Tantalum capacitors are available in a wide range of voltage ratings, making them suitable for various applications.

3. Temperature Stability

These capacitors exhibit excellent temperature stability, ensuring consistent performance across a range of operating conditions.

III. Current Market Landscape

A. Global Market Size and Growth Rate

The global tantalum capacitor market has been experiencing steady growth, driven by the increasing demand for electronic devices. According to recent market research, the market is projected to grow at a compound annual growth rate (CAGR) of approximately 6% over the next five years.

B. Key Players in the Market

1. Major Manufacturers

Several key players dominate the tantalum capacitor market, including KEMET Corporation, Vishay Intertechnology, and AVX Corporation. These companies are known for their innovative products and strong market presence.

2. Market Share Analysis

Market share analysis indicates that KEMET Corporation holds a significant portion of the market, followed closely by Vishay and AVX. These companies are continuously investing in research and development to enhance their product offerings.

C. Regional Market Insights

1. North America

North America is one of the largest markets for tantalum capacitors, driven by the presence of major electronics manufacturers and a growing demand for advanced electronic components.

2. Europe

The European market is also witnessing growth, particularly in the automotive and telecommunications sectors, where the demand for reliable capacitors is high.

3. Asia-Pacific

The Asia-Pacific region is expected to experience the fastest growth, fueled by the rapid expansion of the electronics industry in countries like China, Japan, and South Korea.

4. Rest of the World

Other regions, including Latin America and the Middle East, are gradually adopting tantalum capacitors, contributing to the overall market growth.

IV. Applications of Tantalum Capacitors

Tantalum capacitors find applications across various industries, including:

A. Consumer Electronics

In consumer electronics, tantalum capacitors are used in smartphones, tablets, and laptops, where their compact size and high capacitance are essential.

B. Automotive Industry

The automotive sector increasingly relies on tantalum capacitors for advanced driver-assistance systems (ADAS), infotainment systems, and electric vehicles (EVs).

C. Telecommunications

In telecommunications, these capacitors are critical for base stations, routers, and other networking equipment, where reliability and performance are paramount.

D. Industrial Equipment

Tantalum capacitors are used in industrial equipment for power supply circuits, motor drives, and automation systems, ensuring stable operation.

E. Medical Devices

In the medical field, tantalum capacitors are employed in devices such as pacemakers and imaging equipment, where reliability and performance are crucial for patient safety.

V. Drivers of Market Growth

Several factors are driving the growth of the tantalum capacitor market:

A. Increasing Demand for Miniaturization in Electronics

As electronic devices become smaller and more compact, the demand for high-capacitance, space-saving components like tantalum capacitors is on the rise.

B. Growth of the Electric Vehicle Market

The electric vehicle market is expanding rapidly, leading to increased demand for reliable capacitors in battery management systems and power electronics.

C. Advancements in Telecommunications Technology

The rollout of 5G technology and the increasing need for high-speed data transmission are driving the demand for advanced capacitors in telecommunications equipment.

D. Rising Demand in Medical Applications

The growing healthcare sector and the need for advanced medical devices are contributing to the increased demand for tantalum capacitors.

VI. Challenges Facing the Tantalum Capacitor Market

Despite the positive market outlook, several challenges need to be addressed:

A. Supply Chain Issues

1. Raw Material Sourcing

Tantalum is a rare metal, and its sourcing can be challenging due to geopolitical factors and supply chain disruptions.

2. Geopolitical Factors

Political instability in tantalum-producing regions can impact the availability and pricing of raw materials.

B. Competition from Alternative Capacitor Technologies

1. Ceramic Capacitors

Ceramic capacitors are gaining popularity due to their lower cost and size, posing a challenge to the tantalum capacitor market.

2. Aluminum Capacitors

Aluminum capacitors are also a cost-effective alternative, particularly in low-voltage applications.

C. Environmental and Regulatory Concerns

The production of tantalum capacitors raises environmental concerns, and manufacturers must comply with stringent regulations regarding sourcing and manufacturing processes.

VII. Future Trends and Innovations

A. Technological Advancements

1. Enhanced Performance Capacitors

Ongoing research and development efforts are focused on creating tantalum capacitors with enhanced performance characteristics, such as higher capacitance and lower ESR.

2. Eco-friendly Manufacturing Processes

There is a growing emphasis on developing eco-friendly manufacturing processes to reduce the environmental impact of tantalum capacitor production.

B. Market Predictions

1. Expected Growth Rates

The tantalum capacitor market is expected to continue its growth trajectory, with emerging markets contributing significantly to overall demand.

2. Emerging Markets

Countries in Asia-Pacific and Latin America are anticipated to become key players in the tantalum capacitor market as their electronics industries expand.

C. Potential New Applications

As technology evolves, new applications for tantalum capacitors are likely to emerge, particularly in areas such as renewable energy and IoT devices.

VIII. Conclusion

In summary, the market prospects for tantalum capacitors are promising, driven by increasing demand across various industries and technological advancements. While challenges such as supply chain issues and competition from alternative technologies exist, the overall outlook remains positive. Stakeholders in the industry should stay informed about market trends and innovations to capitalize on the growing opportunities in this sector.

IX. References

- Academic Journals

- Industry Reports

- Market Research Studies

This comprehensive overview of tantalum capacitors highlights their significance in the electronics industry and outlines the factors influencing their market prospects. As technology continues to advance, the role of tantalum capacitors will likely become even more critical, making it essential for industry stakeholders to remain proactive in addressing challenges and exploring new opportunities.