Please choose online customer service:

Important Product Categories of Motor Capacitors

I. Introduction

A. Definition of Motor Capacitors

Motor capacitors are electrical components that store and release electrical energy in electric motors. They play a crucial role in enhancing the performance and efficiency of motors by providing the necessary phase shift for starting and running operations.

B. Importance of Motor Capacitors in Electrical Systems

In electrical systems, motor capacitors are essential for the smooth operation of various types of motors, particularly in applications where high starting torque is required. They help in improving the power factor, reducing energy consumption, and ensuring the longevity of the motor.

C. Overview of the Article's Purpose

This article aims to explore the important product categories of motor capacitors, detailing their functions, applications, and specifications. By understanding these categories, users can make informed decisions when selecting the right motor capacitor for their specific needs.

II. Understanding Motor Capacitors

A. What are Motor Capacitors?

1. Function and Role in Electric Motors

Motor capacitors serve two primary functions: they provide the necessary starting torque for electric motors and help maintain the motor's efficiency during operation. They achieve this by creating a phase shift in the electrical current, which is essential for the proper functioning of single-phase motors.

2. Types of Motor Capacitors

Motor capacitors can be broadly classified into several types, each designed for specific applications and operational requirements. The most common types include start capacitors, run capacitors, dual run capacitors, and power factor correction capacitors.

B. How Motor Capacitors Work

1. Basic Principles of Capacitance

Capacitance is the ability of a component to store electrical energy in an electric field. When a voltage is applied across a capacitor, it stores energy until the voltage is removed. In the context of motor capacitors, this stored energy is released to assist in starting the motor or maintaining its operation.

2. Interaction with Electric Motors

Motor capacitors interact with electric motors by creating a phase difference between the current flowing through the motor windings. This phase difference is crucial for generating the necessary torque to start and run the motor efficiently.

III. Key Product Categories of Motor Capacitors

A. Start Capacitors

1. Definition and Function

Start capacitors are designed to provide a boost of energy to start an electric motor. They are typically used in single-phase motors, where they help overcome the initial inertia of the motor.

2. Applications in Single-Phase Motors

Start capacitors are commonly found in applications such as air conditioning units, refrigerators, and other household appliances that require a high starting torque.

3. Characteristics and Specifications

Start capacitors usually have a high capacitance value and a short operational lifespan. They are rated for a specific voltage and must be selected based on the motor's requirements.

B. Run Capacitors

1. Definition and Function

Run capacitors are used to improve the efficiency of electric motors during continuous operation. They provide a steady supply of energy to the motor, ensuring smooth and efficient performance.

2. Applications in Continuous Operation

Run capacitors are commonly used in applications such as fans, pumps, and compressors, where the motor operates continuously.

3. Characteristics and Specifications

Run capacitors typically have a lower capacitance value than start capacitors and are designed for long-term use. They are rated for continuous operation and must be selected based on the motor's specifications.

C. Dual Run Capacitors

1. Definition and Function

Dual run capacitors combine the functions of both start and run capacitors into a single unit. They are designed to provide the necessary energy for both starting and running an electric motor.

2. Applications in HVAC Systems

Dual run capacitors are commonly used in HVAC systems, where they help improve the efficiency of the compressor and fan motors.

3. Characteristics and Specifications

Dual run capacitors are typically rated for higher capacitance values and must be selected based on the specific requirements of the HVAC system.

D. Power Factor Correction Capacitors

1. Definition and Function

Power factor correction capacitors are used to improve the power factor of electrical systems. They help reduce reactive power and improve the overall efficiency of the system.

2. Importance in Industrial Applications

In industrial applications, power factor correction capacitors are essential for reducing energy costs and improving the performance of electrical equipment.

3. Characteristics and Specifications

These capacitors are typically rated for high voltage and capacitance values and must be selected based on the specific requirements of the electrical system.

E. Motor Start Capacitors

1. Definition and Function

Motor start capacitors are specifically designed to provide the necessary energy to start various types of motors. They are essential for applications that require high starting torque.

2. Applications in Various Motor Types

Motor start capacitors are commonly used in applications such as electric lawn mowers, power tools, and other equipment that requires a high starting torque.

3. Characteristics and Specifications

Motor start capacitors are typically rated for high capacitance values and must be selected based on the motor's specifications.

IV. Specialized Motor Capacitors

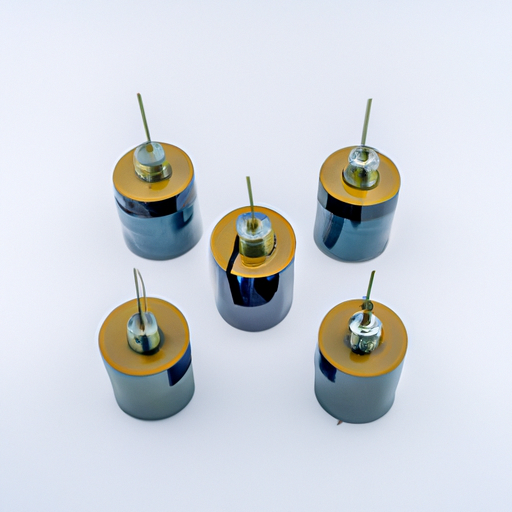

A. Oil-Filled Capacitors

1. Definition and Function

Oil-filled capacitors are designed to operate in high-voltage applications. They use oil as a dielectric medium, which helps improve their performance and reliability.

2. Applications and Advantages

These capacitors are commonly used in industrial applications, such as transformers and power distribution systems, due to their ability to handle high voltage and provide excellent insulation.

B. Film Capacitors

1. Definition and Function

Film capacitors use a thin plastic film as the dielectric material. They are known for their stability and reliability in various applications.

2. Applications and Advantages

Film capacitors are commonly used in applications such as audio equipment, power supplies, and motor drives due to their low loss and high-frequency performance.

C. Electrolytic Capacitors

1. Definition and Function

Electrolytic capacitors are polarized capacitors that use an electrolyte as the dielectric. They are known for their high capacitance values in a compact size.

2. Applications and Advantages

Electrolytic capacitors are commonly used in power supply circuits and motor control applications due to their ability to store large amounts of energy.

V. Factors to Consider When Choosing Motor Capacitors

A. Voltage Rating

The voltage rating of a motor capacitor must match or exceed the voltage of the motor to ensure safe and reliable operation.

B. Capacitance Value

The capacitance value is critical for the performance of the motor. It must be selected based on the motor's specifications and application requirements.

C. Temperature Rating

Motor capacitors are rated for specific temperature ranges. It is essential to choose a capacitor that can operate within the temperature conditions of the application.

D. Physical Size and Mounting Options

The physical size and mounting options of the capacitor must be considered to ensure it fits within the available space in the motor assembly.

E. Application-Specific Requirements

Different applications may have specific requirements for motor capacitors, such as environmental conditions, frequency of operation, and load characteristics.

VI. Conclusion

A. Recap of the Importance of Motor Capacitors

Motor capacitors are vital components in electric motors, providing the necessary energy for starting and running operations. They enhance the efficiency and performance of motors across various applications.

B. Summary of Key Product Categories

The key product categories of motor capacitors include start capacitors, run capacitors, dual run capacitors, power factor correction capacitors, and specialized capacitors such as oil-filled, film, and electrolytic capacitors.

C. Final Thoughts on Selecting the Right Motor Capacitor for Specific Applications

When selecting a motor capacitor, it is essential to consider factors such as voltage rating, capacitance value, temperature rating, and application-specific requirements. By understanding the different product categories and their functions, users can make informed decisions to ensure optimal motor performance.

VII. References

A. Suggested Reading and Resources

- "Capacitors: Principles and Applications" by John Smith

- "Electric Motor Repair" by Robert Rosenberg

B. Industry Standards and Guidelines

- National Electrical Manufacturers Association (NEMA) Standards

- Institute of Electrical and Electronics Engineers (IEEE) Guidelines

This comprehensive exploration of motor capacitors and their important product categories provides valuable insights for anyone involved in the selection and application of these essential components in electrical systems.