Please choose online customer service:

What are the Advantages of Inductor PPT Products?

I. Introduction

Inductor PPT products, or Power Point Technology products, represent a significant advancement in the field of electrical engineering. Inductors are passive components that store energy in a magnetic field when electrical current flows through them. They play a crucial role in various applications, from power supply systems to radio frequency (RF) circuits. This blog post aims to explore the advantages of inductor PPT products, highlighting their performance, versatility, economic benefits, technological advancements, and environmental considerations.

II. Overview of Inductor Technology

A. Basic Principles of Inductance

Inductance is the property of an electrical conductor that opposes changes in current. When current flows through an inductor, it generates a magnetic field around it. If the current changes, the magnetic field also changes, inducing a voltage that opposes the change in current. This fundamental principle is what makes inductors essential in managing electrical energy in circuits.

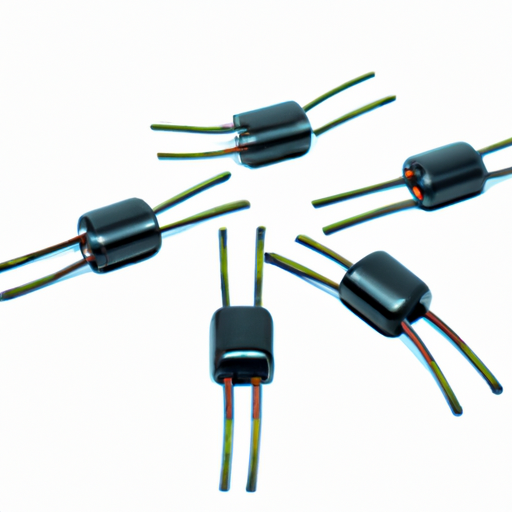

B. Types of Inductors

Inductors come in various types, each suited for specific applications:

1. **Air Core Inductors**: These inductors use air as the core material, making them lightweight and suitable for high-frequency applications.

2. **Iron Core Inductors**: With a core made of iron, these inductors provide higher inductance values and are often used in power applications.

3. **Ferrite Core Inductors**: Ferrite cores are made from a ceramic material that offers high magnetic permeability, making them ideal for RF applications.

C. Role of Inductors in Circuits

Inductors are used in various circuit configurations, including filters, oscillators, and transformers. They help in smoothing out voltage fluctuations, storing energy, and managing signal integrity, making them indispensable in modern electronics.

III. Key Advantages of Inductor PPT Products

A. Enhanced Performance

1. Improved Energy Efficiency

Inductor PPT products are designed to optimize energy efficiency. By minimizing energy losses during operation, these inductors help in reducing overall power consumption, which is crucial in applications where energy savings are a priority.

2. Better Signal Integrity

Inductors play a vital role in maintaining signal integrity. They filter out unwanted noise and harmonics, ensuring that the signals transmitted through circuits remain clear and undistorted. This is particularly important in high-frequency applications, where signal fidelity is paramount.

B. Versatility in Applications

Inductor PPT products are versatile and can be used in a wide range of applications:

1. Power Supply Systems

In power supply systems, inductors are used to smooth out voltage and current fluctuations, ensuring a stable output. They are essential in switch-mode power supplies, where they help in energy conversion and regulation.

2. RF Applications

In RF circuits, inductors are used in tuning and filtering applications. They help in selecting specific frequencies and eliminating unwanted signals, making them crucial for communication devices.

3. Audio Equipment

Inductors are also used in audio equipment to filter signals and enhance sound quality. They help in managing the frequency response of audio systems, ensuring a rich and clear sound.

C. Size and Form Factor

1. Miniaturization Trends

With the ongoing trend towards miniaturization in electronics, inductor PPT products have adapted to meet these demands. They are available in smaller sizes without compromising performance, making them suitable for compact devices.

2. Space-Saving Designs

The compact design of inductor PPT products allows for more efficient use of space in electronic devices. This is particularly beneficial in applications where board space is limited, such as smartphones and wearable technology.

D. Thermal Management

1. Heat Dissipation Properties

Inductor PPT products are designed with thermal management in mind. They have excellent heat dissipation properties, which help in maintaining optimal operating temperatures and prolonging the lifespan of the components.

2. Operating Temperature Range

These inductors can operate effectively across a wide temperature range, making them suitable for various environments, from consumer electronics to industrial applications.

E. Reliability and Longevity

1. Durability in Harsh Environments

Inductor PPT products are built to withstand harsh conditions, including extreme temperatures, humidity, and vibrations. This durability makes them ideal for use in industrial and automotive applications.

2. Low Failure Rates

The reliability of inductor PPT products is a significant advantage. They have low failure rates, which translates to reduced maintenance costs and increased uptime for systems that rely on them.

IV. Economic Benefits

A. Cost-Effectiveness

1. Reduced Material Costs

Inductor PPT products are often made from cost-effective materials, which helps in reducing overall production costs. This cost-effectiveness is beneficial for manufacturers looking to optimize their budgets.

2. Lower Maintenance Expenses

The reliability and longevity of inductor PPT products lead to lower maintenance expenses. Fewer failures mean less downtime and reduced costs associated with repairs and replacements.

B. Scalability for Mass Production

1. Adaptability to Different Manufacturing Processes

Inductor PPT products can be easily adapted to various manufacturing processes, making them suitable for mass production. This adaptability allows manufacturers to scale up production to meet market demands efficiently.

2. Meeting Market Demand

As the demand for electronic devices continues to grow, the scalability of inductor PPT products ensures that manufacturers can keep pace with market needs without compromising quality.

V. Technological Advancements

A. Innovations in Inductor Design

1. Use of Advanced Materials

Recent advancements in materials science have led to the development of inductors made from advanced materials that enhance performance and efficiency. These materials contribute to better energy storage and reduced losses.

2. Integration with Other Components

Inductor PPT products are increasingly being integrated with other components, such as capacitors and resistors, to create compact and efficient circuit designs. This integration simplifies circuit layouts and improves overall performance.

B. Smart Inductor Technologies

1. Self-Adjusting Inductors

Innovations in smart inductor technologies have led to the development of self-adjusting inductors that can adapt to changing circuit conditions. This capability enhances performance and efficiency in dynamic applications.

2. Digital Control Systems

The integration of digital control systems with inductors allows for precise management of inductance values, improving the overall functionality of electronic devices.

VI. Environmental Considerations

A. Eco-Friendly Manufacturing Processes

Many manufacturers of inductor PPT products are adopting eco-friendly manufacturing processes that minimize waste and reduce environmental impact. This commitment to sustainability is becoming increasingly important in today’s market.

B. Recyclability of Inductor Materials

The materials used in inductor PPT products are often recyclable, contributing to a circular economy. This recyclability helps in reducing the environmental footprint of electronic devices.

C. Energy Savings and Sustainability

By improving energy efficiency, inductor PPT products contribute to energy savings and sustainability. Their role in reducing power consumption aligns with global efforts to promote environmentally friendly technologies.

VII. Challenges and Limitations

A. Potential Drawbacks of Inductor PPT Products

1. Size Constraints in Certain Applications

While inductor PPT products are designed for miniaturization, there may still be size constraints in specific applications where space is extremely limited.

2. Frequency Limitations

Inductors have inherent frequency limitations, which can restrict their use in very high-frequency applications. Understanding these limitations is crucial for engineers when designing circuits.

B. Comparison with Alternative Technologies

1. Capacitors

While inductors are essential for certain applications, capacitors may be preferred in others due to their ability to store and release energy quickly. The choice between inductors and capacitors depends on the specific requirements of the circuit.

2. Transformers

Transformers serve a different purpose than inductors, primarily used for voltage conversion. However, both components are essential in electrical engineering, and their use depends on the application.

VIII. Conclusion

In conclusion, inductor PPT products offer numerous advantages that make them indispensable in modern electronics. Their enhanced performance, versatility, economic benefits, and technological advancements position them as key components in various applications. As the demand for efficient and reliable electronic devices continues to grow, the importance of inductors in electrical engineering will only increase. The future outlook for inductor PPT products is promising, with ongoing innovations and a commitment to sustainability paving the way for even greater advancements in the field.

IX. References

- Academic Journals

- Industry Reports

- Technical Manuals and Guides

This blog post provides a comprehensive overview of the advantages of inductor PPT products, emphasizing their significance in the ever-evolving landscape of electrical engineering and technology.