Please choose online customer service:

What are the Purchasing Models of the Latest Magnetic Bead Inductor Equipment Components?

I. Introduction

In the realm of electronics, magnetic bead inductors play a pivotal role in ensuring the functionality and reliability of devices. These components are essential for noise suppression, signal integrity, and power management, making them indispensable in various applications, from consumer electronics to industrial machinery. As the demand for high-performance electronic devices continues to rise, understanding the purchasing models for magnetic bead inductor equipment components becomes crucial for manufacturers and engineers alike. This blog post will explore the different purchasing models available in the industry, their advantages and disadvantages, and the factors influencing purchasing decisions.

II. Understanding Magnetic Bead Inductors

A. Functionality and Applications

Magnetic bead inductors are passive components that help filter out unwanted noise in electronic circuits. They are particularly effective in high-frequency applications, where electromagnetic interference (EMI) can disrupt signal integrity. The primary functions of magnetic bead inductors include:

1. **Noise Suppression**: By providing a high impedance path to high-frequency noise, magnetic bead inductors help maintain the clarity of signals in electronic devices.

2. **Signal Integrity**: They ensure that signals remain clean and undistorted, which is critical for the performance of communication devices, computers, and other electronic systems.

3. **Power Management**: Magnetic bead inductors are used in power supply circuits to smooth out voltage fluctuations, enhancing the overall efficiency of power management systems.

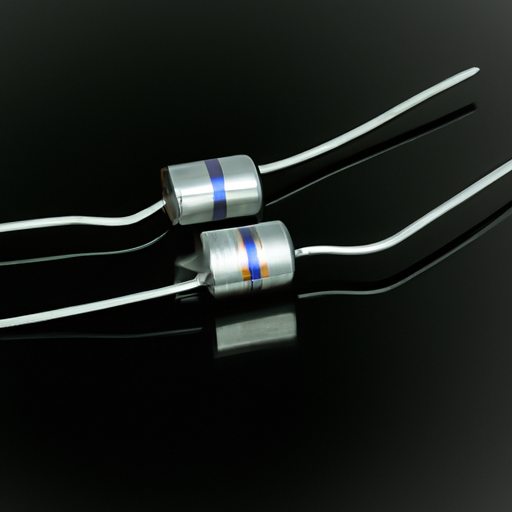

B. Types of Magnetic Bead Inductors

There are several types of magnetic bead inductors, each designed for specific applications:

1. **Ferrite Beads**: These are commonly used for EMI suppression in power lines and signal lines. They are effective at high frequencies and are often found in consumer electronics.

2. **Common Mode Chokes**: These inductors are used to filter out common mode noise in differential signal lines, making them essential in communication systems.

3. **Differential Mode Chokes**: Designed to suppress differential mode noise, these inductors are crucial in applications where signal integrity is paramount.

III. Market Trends and Innovations

A. Recent Advancements in Magnetic Bead Inductor Technology

The magnetic bead inductor market has seen significant advancements in recent years. Innovations in materials and manufacturing processes have led to the development of smaller, more efficient inductors capable of operating at higher frequencies. These advancements are driven by the increasing demand for compact electronic devices that do not compromise on performance.

B. Impact of Miniaturization and High-Frequency Applications

As electronic devices become smaller and more powerful, the need for miniaturized components has grown. Magnetic bead inductors are now being designed to fit into tighter spaces while maintaining their effectiveness. Additionally, the rise of high-frequency applications, such as 5G technology and IoT devices, has necessitated the development of inductors that can handle higher frequencies without losing performance.

C. Sustainability and Eco-Friendly Materials in Manufacturing

With growing concerns about environmental sustainability, manufacturers are increasingly focusing on eco-friendly materials and processes. The use of recyclable materials and energy-efficient manufacturing techniques is becoming a priority in the production of magnetic bead inductors, aligning with global sustainability goals.

IV. Purchasing Models

A. Direct Purchasing

1. Definition and Process

Direct purchasing involves buying magnetic bead inductors directly from manufacturers. This model allows companies to establish a direct relationship with suppliers, ensuring better communication and potentially lower costs.

2. Advantages and Disadvantages

**Advantages**:

- Cost savings due to the elimination of middlemen.

- Direct access to manufacturer support and expertise.

- Customization options for specific needs.

**Disadvantages**:

- Higher minimum order quantities (MOQs).

- Longer lead times for production and delivery.

- Limited flexibility in changing orders.

B. Distributor Partnerships

1. Role of Distributors in the Supply Chain

Distributors act as intermediaries between manufacturers and end-users. They stock a variety of magnetic bead inductors from multiple manufacturers, providing customers with a one-stop-shop for their component needs.

2. Benefits of Using Distributors

Convenience: Distributors often have a wide range of products available, making it easier for companies to find the right components.

Reduced Lead Times: With stock on hand, distributors can provide quicker delivery times.

Technical Support: Many distributors offer technical assistance, helping customers select the right components for their applications.

C. Online Marketplaces

1. Overview of Popular Platforms

Online marketplaces such as Digi-Key, Mouser, and Alibaba have become popular platforms for purchasing magnetic bead inductors. These platforms allow customers to compare products from various manufacturers easily.

2. Pros and Cons of Online Purchasing

**Pros**:

- Easy access to a wide range of products.

- Competitive pricing due to multiple sellers.

- User reviews and ratings can guide purchasing decisions.

**Cons**:

- Potential for counterfeit products.

- Limited customer support compared to direct purchasing.

- Shipping costs and lead times can vary significantly.

D. Custom Manufacturing

1. When to Consider Custom Solutions

Custom manufacturing is an option for companies with specific requirements that off-the-shelf products cannot meet. This model is ideal for specialized applications or unique design constraints.

2. Process and Lead Times

The custom manufacturing process typically involves close collaboration between the customer and the manufacturer. Lead times can vary based on complexity, but they are generally longer than standard purchasing models.

E. Bulk Purchasing and Long-term Contracts

1. Cost Benefits and Inventory Management

Bulk purchasing allows companies to buy large quantities of magnetic bead inductors at discounted rates. Long-term contracts can also secure favorable pricing and ensure a steady supply of components.

2. Risks and Considerations

While bulk purchasing can lead to cost savings, it also carries risks, such as overstocking and potential obsolescence of components. Companies must carefully assess their inventory needs and market trends before committing to large orders.

V. Factors Influencing Purchasing Decisions

Several factors influence the purchasing decisions of companies when it comes to magnetic bead inductors:

A. Quality and Reliability of Components

The quality and reliability of magnetic bead inductors are paramount. Companies must ensure that the components they purchase meet industry standards and perform consistently in their applications.

B. Pricing and Budget Constraints

Pricing is a critical factor in purchasing decisions. Companies must balance the need for high-quality components with their budget constraints, often seeking the best value for their investment.

C. Supplier Reputation and Support

The reputation of suppliers plays a significant role in purchasing decisions. Companies often prefer to work with established suppliers known for their reliability and customer support.

D. Lead Times and Delivery Schedules

Lead times and delivery schedules can impact production timelines. Companies must consider how quickly they need components and whether suppliers can meet those timelines.

E. Compliance with Industry Standards and Regulations

Compliance with industry standards and regulations is essential, especially in sectors such as automotive and aerospace. Companies must ensure that the magnetic bead inductors they purchase meet all necessary certifications.

VI. Case Studies

A. Example of a Successful Purchasing Model in a Tech Company

A leading tech company successfully implemented a distributor partnership model to streamline its procurement process for magnetic bead inductors. By working closely with a reputable distributor, the company was able to reduce lead times and improve inventory management, resulting in significant cost savings and enhanced product quality.

B. Lessons Learned from a Failed Purchasing Strategy

In contrast, a manufacturer that relied solely on direct purchasing faced challenges due to long lead times and inflexible order quantities. This approach led to production delays and increased costs, highlighting the importance of evaluating different purchasing models.

C. Comparative Analysis of Different Purchasing Models in Real-World Scenarios

A comparative analysis of various purchasing models reveals that a hybrid approach often yields the best results. Companies that combine direct purchasing for high-volume needs with distributor partnerships for flexibility and online marketplaces for quick access to components tend to achieve optimal outcomes.

VII. Future Outlook

A. Predictions for the Magnetic Bead Inductor Market

The magnetic bead inductor market is expected to grow significantly in the coming years, driven by advancements in technology and increasing demand for high-performance electronic devices. As industries continue to evolve, the need for innovative solutions will shape the future of magnetic bead inductor procurement.

B. Emerging Technologies and Their Impact on Purchasing Models

Emerging technologies, such as AI and machine learning, are poised to revolutionize purchasing models. These technologies can enhance supply chain management, optimize inventory levels, and improve decision-making processes.

C. The Role of AI and Data Analytics in Optimizing Purchasing Decisions

AI and data analytics can provide valuable insights into market trends, supplier performance, and customer preferences. By leveraging these tools, companies can make more informed purchasing decisions and adapt their strategies to changing market conditions.

VIII. Conclusion

In conclusion, the purchasing models for magnetic bead inductor equipment components are diverse and evolving. Companies must carefully consider their specific needs, market trends, and the advantages and disadvantages of each model. By choosing the right purchasing strategy, businesses can enhance their procurement processes, improve product quality, and ultimately drive success in the competitive electronics market. As technology continues to advance, staying informed about the latest trends and innovations will be essential for making informed purchasing decisions in the future.