What are the Product Standards for Inductor Pictures?

I. Introduction

Inductors are fundamental components in electronic circuits, playing a crucial role in energy storage, filtering, and signal processing. As passive components, they store energy in a magnetic field when electrical current flows through them. The importance of inductors cannot be overstated, as they are integral to the functioning of various devices, from power supplies to radio transmitters. Given their significance, the visual representation of inductors—particularly in product images—must adhere to specific standards to ensure clarity, accuracy, and compliance with industry regulations. This blog post will explore the product standards for inductor pictures, emphasizing their importance and providing guidelines for capturing high-quality images.

II. Understanding Inductors

A. Basic Principles of Inductance

Inductance is the property of an electrical conductor that opposes changes in current. When current flows through an inductor, it generates a magnetic field around it. If the current changes, the magnetic field also changes, inducing a voltage that opposes the change in current. This principle is fundamental to the operation of inductors in various applications.

B. Types of Inductors

Inductors come in various types, each suited for specific applications:

1. **Air-core inductors**: These inductors do not use a magnetic core, relying solely on the air surrounding the coil. They are often used in high-frequency applications due to their low losses.

2. **Iron-core inductors**: These inductors use an iron core to increase inductance. They are commonly found in power applications where higher inductance values are required.

3. **Ferrite-core inductors**: Ferrite cores are made from a ceramic material that is magnetically conductive. These inductors are used in high-frequency applications and are known for their efficiency.

4. **Toroidal inductors**: These inductors have a doughnut-shaped core, which helps to minimize electromagnetic interference. They are often used in audio equipment and power supplies.

C. Applications of Inductors in Various Industries

Inductors are used across multiple industries, including telecommunications, automotive, consumer electronics, and renewable energy. They are essential in power supplies, filters, transformers, and oscillators, demonstrating their versatility and importance in modern technology.

III. Importance of Product Standards

A. Definition of Product Standards

Product standards are established criteria that ensure the quality, safety, and efficiency of products. They provide guidelines for manufacturers to follow, ensuring that products meet specific requirements and perform as intended.

B. Role of Product Standards in Manufacturing and Quality Assurance

In the manufacturing process, adhering to product standards is crucial for quality assurance. Standards help manufacturers maintain consistency in production, reduce defects, and enhance customer satisfaction. For inductors, product standards ensure that the components function correctly and safely in their intended applications.

C. Benefits of Adhering to Product Standards for Inductors

By adhering to product standards, manufacturers can improve their reputation, reduce liability risks, and gain a competitive edge in the market. Additionally, compliance with standards can facilitate international trade, as products that meet recognized standards are often more readily accepted in global markets.

IV. Key Product Standards for Inductor Pictures

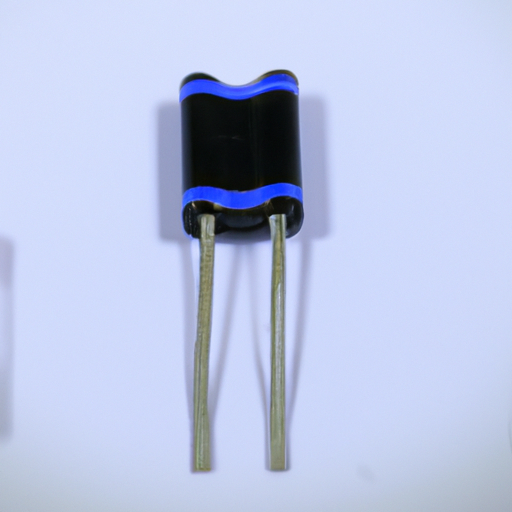

A. Visual Representation Standards

1. **Clarity and resolution**: High-resolution images are essential for accurately representing inductors. Clear images allow potential customers to examine details, such as winding patterns and terminal connections.

2. **Color accuracy**: Accurate color representation is vital for distinguishing between different inductor types and specifications. Manufacturers should ensure that their images reflect the true colors of the components.

3. **Scale and dimensions**: Including a scale reference in images helps viewers understand the size of the inductor. This can be achieved by placing a ruler or a common object next to the inductor in the photograph.

B. Compliance with Industry Standards

1. **International Electrotechnical Commission (IEC)**: The IEC sets international standards for electrical and electronic products, including inductors. Compliance with IEC standards ensures that products meet global safety and performance requirements.

2. **Institute of Electrical and Electronics Engineers (IEEE)**: IEEE standards focus on the technical aspects of electrical and electronic devices. Adhering to these standards can enhance the credibility of inductor products.

3. **American National Standards Institute (ANSI)**: ANSI develops standards for various industries, including electronics. Compliance with ANSI standards can help manufacturers demonstrate their commitment to quality.

C. Safety and Environmental Standards

1. **RoHS compliance**: The Restriction of Hazardous Substances (RoHS) directive limits the use of specific hazardous materials in electrical and electronic products. Ensuring that inductors comply with RoHS is essential for environmental safety.

2. **REACH regulations**: The Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH) regulation aims to protect human health and the environment from chemical risks. Compliance with REACH is crucial for manufacturers operating in the European market.

3. **UL certification**: Underwriters Laboratories (UL) certification indicates that a product has been tested for safety and performance. Obtaining UL certification for inductors can enhance their marketability.

V. Guidelines for Capturing Inductor Pictures

A. Equipment and Tools Needed

1. **Cameras and lenses**: A high-quality camera with a macro lens is ideal for capturing detailed images of inductors. DSLRs or mirrorless cameras are recommended for their versatility and image quality.

2. **Lighting setup**: Proper lighting is essential for showcasing the details of inductors. Soft, diffused lighting can help eliminate harsh shadows and reflections.

3. **Background and staging**: A clean, uncluttered background allows the inductor to stand out. Neutral colors, such as white or gray, are often preferred for product photography.

B. Techniques for Effective Photography

1. **Focus and depth of field**: Use a shallow depth of field to blur the background and draw attention to the inductor. Ensure that the inductor is in sharp focus to highlight its features.

2. **Angles and perspectives**: Experiment with different angles to find the most flattering view of the inductor. Capturing images from multiple perspectives can provide a comprehensive view of the product.

3. **Post-processing tips**: Use photo editing software to enhance images, adjusting brightness, contrast, and color balance as needed. However, avoid over-editing, as this can misrepresent the product.

VI. Common Mistakes in Inductor Photography

A. Poor Lighting Conditions

Inadequate lighting can result in dark, unclear images that fail to showcase the inductor's details. Always ensure proper lighting to achieve high-quality photographs.

B. Inaccurate Color Representation

Using incorrect white balance settings can lead to color inaccuracies. Always check the color settings on your camera and adjust them as necessary to ensure true-to-life colors.

C. Lack of Scale Reference

Failing to include a scale reference can leave viewers unsure of the inductor's size. Always incorporate a common object or measuring tool in the frame.

D. Overly Cluttered Backgrounds

A busy background can distract from the inductor itself. Keep backgrounds simple and clean to maintain focus on the product.

VII. Case Studies

A. Examples of High-Quality Inductor Pictures

High-quality inductor images often feature clear details, accurate colors, and appropriate scale references. These images effectively communicate the product's specifications and appeal to potential customers.

B. Analysis of Pictures that Fail to Meet Standards

Images that lack clarity, have poor lighting, or misrepresent colors can lead to customer confusion and dissatisfaction. Analyzing these images can provide valuable lessons for improving product photography.

C. Lessons Learned from Case Studies

Case studies highlight the importance of adhering to product standards in photography. By learning from both successful and unsuccessful examples, manufacturers can refine their visual representation strategies.

VIII. Conclusion

In conclusion, product standards for inductor pictures are essential for ensuring clarity, accuracy, and compliance with industry regulations. By understanding the importance of these standards and following best practices for capturing high-quality images, manufacturers can enhance their product presentations and improve customer satisfaction. Prioritizing quality in visual representation not only benefits manufacturers but also fosters trust and confidence among consumers.

IX. References

- International Electrotechnical Commission (IEC)

- Institute of Electrical and Electronics Engineers (IEEE)

- American National Standards Institute (ANSI)

- RoHS Directive

- REACH Regulation

- Underwriters Laboratories (UL)

By adhering to these guidelines and standards, manufacturers and marketers can effectively showcase their inductors, ultimately leading to better market performance and customer engagement.

What are the Product Standards for Inductor Pictures?

I. Introduction

Inductors are fundamental components in electronic circuits, playing a crucial role in energy storage, filtering, and signal processing. As passive components, they store energy in a magnetic field when electrical current flows through them. The importance of inductors cannot be overstated, as they are integral to the functioning of various devices, from power supplies to radio transmitters. Given their significance, the visual representation of inductors—particularly in product images—must adhere to specific standards to ensure clarity, accuracy, and compliance with industry regulations. This blog post will explore the product standards for inductor pictures, emphasizing their importance and providing guidelines for capturing high-quality images.

II. Understanding Inductors

A. Basic Principles of Inductance

Inductance is the property of an electrical conductor that opposes changes in current. When current flows through an inductor, it generates a magnetic field around it. If the current changes, the magnetic field also changes, inducing a voltage that opposes the change in current. This principle is fundamental to the operation of inductors in various applications.

B. Types of Inductors

Inductors come in various types, each suited for specific applications:

1. **Air-core inductors**: These inductors do not use a magnetic core, relying solely on the air surrounding the coil. They are often used in high-frequency applications due to their low losses.

2. **Iron-core inductors**: These inductors use an iron core to increase inductance. They are commonly found in power applications where higher inductance values are required.

3. **Ferrite-core inductors**: Ferrite cores are made from a ceramic material that is magnetically conductive. These inductors are used in high-frequency applications and are known for their efficiency.

4. **Toroidal inductors**: These inductors have a doughnut-shaped core, which helps to minimize electromagnetic interference. They are often used in audio equipment and power supplies.

C. Applications of Inductors in Various Industries

Inductors are used across multiple industries, including telecommunications, automotive, consumer electronics, and renewable energy. They are essential in power supplies, filters, transformers, and oscillators, demonstrating their versatility and importance in modern technology.

III. Importance of Product Standards

A. Definition of Product Standards

Product standards are established criteria that ensure the quality, safety, and efficiency of products. They provide guidelines for manufacturers to follow, ensuring that products meet specific requirements and perform as intended.

B. Role of Product Standards in Manufacturing and Quality Assurance

In the manufacturing process, adhering to product standards is crucial for quality assurance. Standards help manufacturers maintain consistency in production, reduce defects, and enhance customer satisfaction. For inductors, product standards ensure that the components function correctly and safely in their intended applications.

C. Benefits of Adhering to Product Standards for Inductors

By adhering to product standards, manufacturers can improve their reputation, reduce liability risks, and gain a competitive edge in the market. Additionally, compliance with standards can facilitate international trade, as products that meet recognized standards are often more readily accepted in global markets.

IV. Key Product Standards for Inductor Pictures

A. Visual Representation Standards

1. **Clarity and resolution**: High-resolution images are essential for accurately representing inductors. Clear images allow potential customers to examine details, such as winding patterns and terminal connections.

2. **Color accuracy**: Accurate color representation is vital for distinguishing between different inductor types and specifications. Manufacturers should ensure that their images reflect the true colors of the components.

3. **Scale and dimensions**: Including a scale reference in images helps viewers understand the size of the inductor. This can be achieved by placing a ruler or a common object next to the inductor in the photograph.

B. Compliance with Industry Standards

1. **International Electrotechnical Commission (IEC)**: The IEC sets international standards for electrical and electronic products, including inductors. Compliance with IEC standards ensures that products meet global safety and performance requirements.

2. **Institute of Electrical and Electronics Engineers (IEEE)**: IEEE standards focus on the technical aspects of electrical and electronic devices. Adhering to these standards can enhance the credibility of inductor products.

3. **American National Standards Institute (ANSI)**: ANSI develops standards for various industries, including electronics. Compliance with ANSI standards can help manufacturers demonstrate their commitment to quality.

C. Safety and Environmental Standards

1. **RoHS compliance**: The Restriction of Hazardous Substances (RoHS) directive limits the use of specific hazardous materials in electrical and electronic products. Ensuring that inductors comply with RoHS is essential for environmental safety.

2. **REACH regulations**: The Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH) regulation aims to protect human health and the environment from chemical risks. Compliance with REACH is crucial for manufacturers operating in the European market.

3. **UL certification**: Underwriters Laboratories (UL) certification indicates that a product has been tested for safety and performance. Obtaining UL certification for inductors can enhance their marketability.

V. Guidelines for Capturing Inductor Pictures

A. Equipment and Tools Needed

1. **Cameras and lenses**: A high-quality camera with a macro lens is ideal for capturing detailed images of inductors. DSLRs or mirrorless cameras are recommended for their versatility and image quality.

2. **Lighting setup**: Proper lighting is essential for showcasing the details of inductors. Soft, diffused lighting can help eliminate harsh shadows and reflections.

3. **Background and staging**: A clean, uncluttered background allows the inductor to stand out. Neutral colors, such as white or gray, are often preferred for product photography.

B. Techniques for Effective Photography

1. **Focus and depth of field**: Use a shallow depth of field to blur the background and draw attention to the inductor. Ensure that the inductor is in sharp focus to highlight its features.

2. **Angles and perspectives**: Experiment with different angles to find the most flattering view of the inductor. Capturing images from multiple perspectives can provide a comprehensive view of the product.

3. **Post-processing tips**: Use photo editing software to enhance images, adjusting brightness, contrast, and color balance as needed. However, avoid over-editing, as this can misrepresent the product.

VI. Common Mistakes in Inductor Photography

A. Poor Lighting Conditions

Inadequate lighting can result in dark, unclear images that fail to showcase the inductor's details. Always ensure proper lighting to achieve high-quality photographs.

B. Inaccurate Color Representation

Using incorrect white balance settings can lead to color inaccuracies. Always check the color settings on your camera and adjust them as necessary to ensure true-to-life colors.

C. Lack of Scale Reference

Failing to include a scale reference can leave viewers unsure of the inductor's size. Always incorporate a common object or measuring tool in the frame.

D. Overly Cluttered Backgrounds

A busy background can distract from the inductor itself. Keep backgrounds simple and clean to maintain focus on the product.

VII. Case Studies

A. Examples of High-Quality Inductor Pictures

High-quality inductor images often feature clear details, accurate colors, and appropriate scale references. These images effectively communicate the product's specifications and appeal to potential customers.

B. Analysis of Pictures that Fail to Meet Standards

Images that lack clarity, have poor lighting, or misrepresent colors can lead to customer confusion and dissatisfaction. Analyzing these images can provide valuable lessons for improving product photography.

C. Lessons Learned from Case Studies

Case studies highlight the importance of adhering to product standards in photography. By learning from both successful and unsuccessful examples, manufacturers can refine their visual representation strategies.

VIII. Conclusion

In conclusion, product standards for inductor pictures are essential for ensuring clarity, accuracy, and compliance with industry regulations. By understanding the importance of these standards and following best practices for capturing high-quality images, manufacturers can enhance their product presentations and improve customer satisfaction. Prioritizing quality in visual representation not only benefits manufacturers but also fosters trust and confidence among consumers.

IX. References

- International Electrotechnical Commission (IEC)

- Institute of Electrical and Electronics Engineers (IEEE)

- American National Standards Institute (ANSI)

- RoHS Directive

- REACH Regulation

- Underwriters Laboratories (UL)

By adhering to these guidelines and standards, manufacturers and marketers can effectively showcase their inductors, ultimately leading to better market performance and customer engagement.